Determine Diameter and CFM of each Branch 4. Designing Your Dust Collection System.

System And Ducting Design Scientific Dust Collectors

Our dust collector ducting is designed to withstand high air pressure minimize air resistance and reduce static pressure loss making it ideal for material handling.

. Dust Collector Design Software Application Management. Dust Collector Design Software Advertisement Web Design Software v90 ABCWebWizard Web software is superior easy-to-use web design software that lets anyone create professional-looking web pages in minutes. Total collection efficiency sample calculation particle size range particle size fractional efficiencies microns distribution d50 collection collected particulate min max by weight microns by weight by weight 0 5 3 25 2596 078 5 10 5 75 9483 474 10 20 12 15 9879 1185 20 30 19 25 9928 1886 30 40 13 35 9987 1298.

Engineering Drawing areas include. Introduction Cyclones and their design. How to Design A Dust.

The software allows you design best possible Bag Filters by exploiting various design parametersThis package covers Pulse Jet Type of Bag Filter an ideal range of capacity 500 to 250 000 Cubic Meter per hourThis software suitable for all applications like Floor mill to Cement plants Boiler etcWe have covered the. As far as piping that dust collector for 6 it depends on the actual CFM capability of the system most DCs are rated much higher than they actually deliver and the length of your duct. An air-cleaning device used to remove heavy-particulate loadings from exhaust systems prior to discharge.

Structural software to design and calculate the loadings for all of our dust collectors. As we worked with Oneida Air Systems to design a dust-collection system for our photo shop they asked us to try the Supercell cyclone opener photo a new small-shop approach to sucking up dust. Plasma cutting and Vacuum systems emission factors by Thompson Metal Fab Inc.

In our publication A Scientific Review of Dust Collection The Real Dirt on Dust 2nd Edition we devote an entire Chapter on System Design. Determine Duct Velocity FPM 3. There are two phases to designing your dust collection system.

Rather than a 3450 rpm induction motor spinning a vaned impeller three high-speed universal motors below like those found in a shop vacuum. Leak-tight laser welded seams instead of lock-form or spiral duct - which badly leaks and allows debris harbors and snag opportunities. A dust collection design guide in PDF format originally written by Air Handling Systems - July 17 2001 This document - Designing Your Air Handling Dust System - is a design guide originally written by Air Handling Systems and has been converted into a two page PDF document requires Acrobat Reader.

The Four Key Baghouse System Design Variables For a dust collection system to function ade- quately engineers must design and operate the system to maintain the 4 key design parameters of CFM FPM Vacuum Pressure and Air to Cloth Ratio or AC. SDCs Engineering Department utilizes RISA Technologies Inc. ASME based round dust collectors design software.

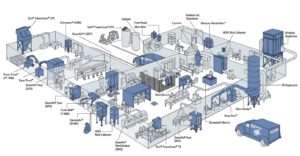

Draw a floor plan of your shop 2. There are different processes for collecting the dust in a gas stream see global overview here among them cyclones are probably one of the most widespread solution in any industryCyclone dust collectors are fairly simple from a mechanical point of view and therefore generally provide a cost effective solution. Illustration of components for a dust collection system Andrew et al.

ABSTEL-GLYDE was formed to provide quality Engineering Technical drawing and Operations advice to Industry. Dust Collector Design Software. 2012 Hood entry loss.

Designing Your Dust Collection System There are five simple steps to designing an effective and efficient dust collection system. Local dealer support. Portable Dust Collector emission factors are provided in the San Joaquin Valley - Unified Air Pollution Control District Publication Guideline for Expedited Application Review GEAR 16 Woodworking Operations April 28 2008.

In Chapter 4 of our book we break down the Physics of System Ducting Design and make it simple to understand. With ABCWebWizards easy to use WYSIWYG layout and dazzling effects building a web site is easy and funAnd ABCWebWizards. Easy fast to install just clamp together no rivets screws or welding needed.

Nordfab dust collection ductwork includes fittings and pipes that range from 3 - 24 in diameter and feature double-rolled connecting edges that clamp into place to provide heavy-duty seals. One of the tools we use to make calculations for dust collector or fume collection system design is SolidWorks 3D Modelling software. At SDC we have the Engineering expertise to design your dust collector to suit your needs and provide the structural calculations along with it for No Extra Charge.

Determine Diameter and CFM of Main Duct 5. Proper hood design system sizing using the Velocity Pressure Method duct routing and sizing for maintaining balanced air flows equipment specifications dust collector fan etc and any explosion protection equipment that should be included. The first phase is sizing your duct work for adequate volume and velocity of flow for the type of dust you will be creating.

Because the program is web based users can login from any browser using their unique user ID and password. Click Here to get more information on SDCs book. For more information Email.

Generates custom quotes using your logo and contact info Creates parts list and install order documents Users can access DuctQuote to design dustmistfume collection systems at a rate of 20 machine connections per hour. Adaptable to your existing ductwork. SWCAA ID - 954.

SDC Engineering has the capability and. These 3D models are conceptual and help the designers manufacturers client and installers to have the. By using our comprehensive library of solid parts this design software allows us to generate 3-dimensional models of the proposed system.

Changes to any of these key sys- tem parameters will result in systemwide perform- ance issues. Dust Collector Design Software. The second phase is computing the static pressure SP of your system to determine the size and power of your dust collection unit.

The software allows you design best possible Bag Filters by exploiting various design parametersThis package covers Pulse Jet Type of Bag Filter an ideal range of capacity 500 to 250 000 Cubic Meter per hourThis software suitable for all. Dust Collector Duct Design. Figure System Resistance SP - Static Pressure.

Dust collector exhaust hood ductwork air mover fan plugging buildup design. Companies that specialize in dust collection are much better versed on duct design and in general where you find snaplock pipe they sell larger size pipe. After the design is complete Airdusco EDS will provide a complete.

Civil and Structural. Abstel covers the major aspects of Engineering strategy Operations Management and Engineering Design. Clamp together ducting.

Bag Filter Design Software Youtube

Dust Collection Design Ingenium Design

Dust Collector Design Grabcad Tutorials

Dust Collection System Design 3d Modelling Ast Engineering Inc

Cyclone Software For Design Modelling And Optimisation Of Gas Solid Separator Cyclone

.jpg)

System And Ducting Design Scientific Dust Collectors

Dust Collector Systems Design And Calculation Tutorials Youtube

0 komentar

Posting Komentar